New York - On Manhattan's Upper West Side, an unassuming residential high-rise appears no different from other luxurious buildings at first glance. Its grand lobby, adorned with tapestries and marble, welcomes visitors with a doorman.

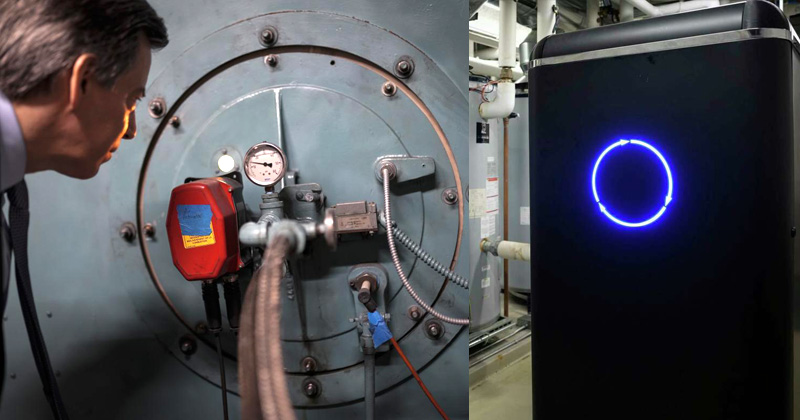

However, below the surface lies a distinctive installation found in very few buildings worldwide, let alone in New York City. In a bold attempt to significantly diminish emissions, the building's owners have introduced a complex network of interconnected pipes and tanks in the basement. This innovative system captures carbon dioxide from the building's substantial gas-fired boilers, preventing its release into the atmosphere through the chimney.

The objective is to prevent the release of climate-warming gases into the atmosphere, and the urgency to reduce emissions from skyscrapers like these in a predominantly vertical city is paramount. Buildings account for approximately two-thirds of greenhouse gas emissions in New York City, making them the most significant contributor. In addition, buildings in New York State produce more air pollution than those in any other state.

Hence, building owners are required to implement significant reductions starting from the upcoming year, or else they will face increasing fines as stipulated by a recent city legislation. More than half of the buildings in the city, roughly 50,000 structures, fall under the purview of Local Law 97. Similar regulations have been adopted by other cities like Boston and Denver.

Consequently, property managers are in a frenzy to transform the operational practices of their buildings. Some are opting to install carbon capture systems, designed to extract carbon dioxide from the emissions and channel it into tanks. This captured carbon dioxide can then be sold to other companies involved in the production of carbonated beverages, soap, or concrete.

For building owners, this approach offers a means to achieve emission reduction targets without displacing residents for extensive renovation projects. In this particular scenario, the captured carbon dioxide finds a buyer in a concrete manufacturer located in Brooklyn, where it is transformed into a mineral and permanently integrated into the concrete.

"We believe that the key lies in swiftly reducing emissions," stated Brian Asparro, the Chief Operating Officer of CarbonQuest, the company responsible for constructing the system. "Time is not on our side, and this solution can be swiftly and cost-effectively implemented without causing significant disruptions."

However, numerous critics, including representatives from environmental organizations, contend that building managers should go beyond these measures. They argue that for substantial emissions reductions, buildings should undergo extensive upgrades and transition to renewable electricity sources, instead of relying on fossil fuels. Moreover, these critics raise apprehensions regarding the safety implications of storing substantial quantities of carbon dioxide, which can act as an asphyxiant, within densely populated communities.

Anthony Rogers-Wright, the Director of Environmental Justice at New York Lawyers for the Public Interest, stated, "Carbon capture doesn't genuinely reduce emissions; it simply aims to relocate them elsewhere. The emissions remain in existence. It's important to acknowledge that the only effective way to reduce emissions is to cease emitting altogether."

The recognition of carbon capture technology as a valid means of emissions reduction is still uncertain in the eyes of New York City, as the city authorities have yet to make a decision. Brian Asparro and other advocates are actively attempting to convince city officials to accept carbon capture as a legitimate approach.

Seizing the Offender

In the lower level of the apartment building on the Upper West Side, two massive 500-horsepower boilers roar as they burn natural gas, emitting carbon dioxide into the air. According to Asparro, these boilers, which are projected to remain operational for another 10 to 20 years, account for roughly half of the building's emissions.

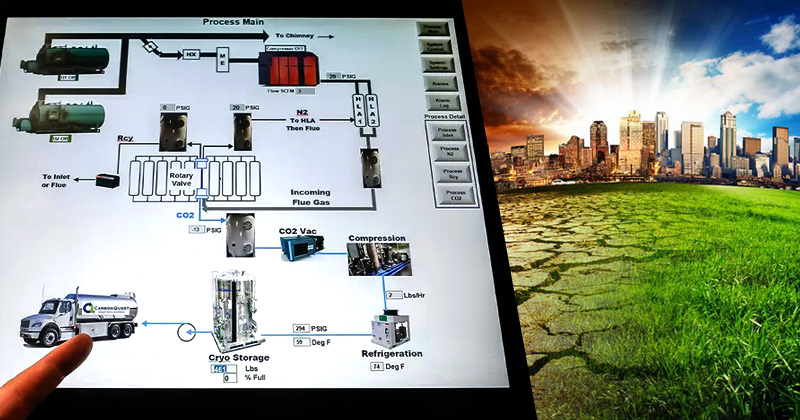

The other half of the emissions, as deemed by the city, is attributed to the power plants that supply electricity to the building. Asparro explained that the carbon capture system installed in the building effectively captures approximately 60% of the emissions from the boilers. Taking into account the electricity required to power the system, the overall emissions reduction achieved by the building is approximately 23%.

"Asparro emphasized that boilers like these are ubiquitous, found in schools and hospitals worldwide," he said. "Reducing emissions poses a significant challenge for buildings."

The carbon dioxide and other gases are diverted from the chimney and directed through pipes into a dedicated room within the building, which has repurposed a few parking spaces to accommodate the carbon capture system. Within this room, the gases pass over a specialized substance that effectively separates the carbon dioxide from the rest. Subsequently, the separated carbon dioxide is subjected to compression and cooled to a frigid temperature of minus 10 degrees Fahrenheit (minus 23 degrees Celsius), transforming it into a liquid state. The liquid carbon dioxide is then stored in tanks for future use. It's important to note that this process consumes energy, and although capturing carbon dioxide does increase the building's electricity consumption, the overall impact of the system still results in reduced emissions for the building.

Additional pipes extend outside the building, terminating in spigots. Once or twice a week, a truck arrives to collect the liquefied CO2 from these spigots. The truck then traverses city streets and crosses a bridge to reach Brooklyn, where the captured carbon dioxide is sold to a concrete manufacturer.

For several decades, carbon capture technology has been employed on an industrial level by oil and gas companies and certain manufacturing plants. Its purpose has been to capture carbon dioxide, a greenhouse gas contributing to climate change, which can then be either sold or utilized to extract additional oil from underground reserves.

However, a new trend is emerging as a few green tech companies and building owners seek to implement this technology on a smaller scale, specifically targeting residential buildings. In compliance with New York City's regulations, buildings larger than 25,000 square feet are required to reduce emissions. An example of such implementation can be found in Minnesota, where the Radisson Blu Mall of America, a hotel, has successfully installed a carbon capture system. This system captures carbon dioxide, which is subsequently utilized in the production of soap.

Building owners who possess the financial capacity to invest in carbon capture equipment can benefit from certain federal tax incentives offered for the installation of such systems. Additionally, NYC Accelerator, a program that assists homeowners and property managers in identifying emission reduction methods, highlights the availability of other incentives to support building upgrades.

In order to minimize energy consumption, the apartment building has implemented various measures, including computerized motors, fans, and pumps, LED lighting, and battery storage, as stated by Josh London, Senior Vice President at Glenwood Management Corp., the company responsible for managing the building. The company has plans to install carbon capture systems in an additional five buildings within the current year.

If no action is taken, similar high-rise buildings could potentially face annual fines of nearly $1 million starting in 2030, as estimated by Asparro.

According to NYC Accelerator, approximately 70% of large buildings in New York City rely on steam boilers fueled by natural gas or oil. Many of these buildings possess heating systems that are over fifty years old, and often they suffer from inadequate maintenance, highlighted Luke Surowiec, the Director of Building Decarbonization at ICF, a consulting firm overseeing NYC Accelerator.

"Our buildings are characterized by their age and inefficiency, and that is the reality we face," Surowiec expressed. "There are numerous untapped opportunities that have yet to be realized."

Transforming into Concrete Minerals

In Brooklyn, the bustling environment of Glenwood Mason Supply Company Inc., an independent concrete manufacturer unrelated to Glenwood Management Corp., is characterized by the rumbling and vibrations caused by yellow machinery in operation. Along a conveyor line, grey blocks clatter while metal gears and motors create a cacophony of sound. Interestingly, birds have found their way into this space and dart between towering piles of blocks.

Amidst this lively atmosphere, a truck arrives to deliver the liquefied carbon dioxide collected from the Manhattan apartment building. With the assistance of equipment provided by CarbonCure, the liquid carbon dioxide is then subjected to compression, transforming it into a solid state.

Within a structure resembling a pizza oven, as the ingredients for concrete mix together, the carbon dioxide, now resembling dry ice, permeates the mixture in a mist-like form. The carbon dioxide undergoes a reaction with calcium ions present in cement, one of the essential components of concrete. This reaction leads to the formation of calcium carbonate, which becomes integrated into the concrete material.

Once the carbon dioxide reaches this mineral state, it becomes securely trapped within the concrete and remains bound unless exposed to temperatures of approximately 900 degrees Celsius (1652 degrees Fahrenheit). According to Claire Nelson, a geochemist specializing in carbon capture at Columbia Climate School, the mineralized carbon dioxide remains stable in this state.

According to Nelson, unless an unlikely event such as a volcanic eruption occurs directly on top of a concrete building, the mineralized carbon will remain permanently embedded within the structure.

Cement, one of the primary components of concrete, accounts for approximately 7% of global greenhouse gas emissions, as reported by a study conducted by the PBL Netherlands Environmental Assessment Agency.

Introducing mineralized carbon dioxide into concrete can help mitigate its carbon footprint, although the reduction is relatively modest. On average, concrete producers implementing CarbonCure technology achieve a carbon footprint reduction of approximately 5% to 6%, as stated by Robert Niven, the CEO of CarbonCure, an organization collaborating with 700 concrete producers across 30 countries.

In addition to their efforts in incorporating mineralized CO2 into their concrete, Glenwood Mason, led by owner Connie Cincotta, implements various measures to further enhance sustainability. One such measure involves reducing the quantity of cement in their concrete mixture by incorporating post-industrial glass, which would otherwise be destined for landfills.

Cincotta explained, "If we can find ways to decrease the amount of cement used in the mixture, it contributes to our sustainability goals."

Glenwood Mason's concrete blocks, enriched with mineralized CO2, have been utilized in the construction of buildings owned by notable entities like Amazon and a charter school in Manhattan, among others.

Uncertainties Persist

Many environmental groups maintain a skeptical stance towards carbon capture and instead advocate for prioritizing investments in renewable energy sources. They also express concerns regarding the safety implications of storing carbon dioxide within residential structures.

An incident in Satartia, Mississippi, in 2020, involving the rupture of a carbon dioxide pipeline, serves as a case in point. According to a report by the Pipeline and Hazardous Materials Safety Administration, 45 individuals sought medical attention at local hospitals, including those who were exposed to a vapor cloud while driving. The report further highlights that individuals exposed to high concentrations of carbon dioxide may experience symptoms such as rapid breathing, confusion, elevated blood pressure, and irregular heartbeats. It is important to note that extremely high concentrations of carbon dioxide can result in asphyxiation and potential loss of life.

The idea of storing concentrated carbon dioxide beneath a residential building raises concerns, particularly because, as Anthony Rogers-Wright pointed out, the situation in Mississippi did not involve people living directly above the storage site. "We're talking about big buildings here in New York City. So the risks are unknown, but they certainly are apparent," he explained.

Furthermore, there is the added risk of potential leaks if a truck transporting carbon dioxide were to be involved in an accident.

Supporters of carbon capture technology argue that there are measures in place to mitigate such risks. Brian Asparro highlighted that the carbon capture technology implemented in the Manhattan apartment building received approval from multiple city agencies, indicating that safeguards are in place.

"As a matter of fact, carbon dioxide is already present in various city settings," he added. "Hospitals, restaurants, breweries— they all employ carbon dioxide in their operations. And this is being done in a reasonably safe and controllable manner."

Nelson, the geochemist from Columbia University who is also involved in a carbon capture company, argues that the risks associated with storing natural gas in basements are more significant compared to storing carbon dioxide. Furthermore, many individuals readily accept the risks associated with natural gas storage.

Advocates argue that the primary hurdle lies in rapidly scaling up various solutions, including carbon capture, to effectively combat climate change.

Therefore, proponents emphasize the need to implement multiple solutions concurrently.

In Manhattan, achieving a complete transition to renewable electricity for the apartment building remains unattainable at present due to the limited availability of renewable energy from the local utility, as stated by London.

He further explained that solar energy requires a larger surface area than what the building can accommodate.

London expressed his intention to procure power from wind farms once they become more widely accessible.

However, he acknowledged that this transition will take a considerable amount of time, and therefore, it is crucial to take immediate action to reduce emissions while awaiting the availability of renewable energy sources.